lumentics Phosphorescent polyester-based powder coating. Phosphorescent coating material for interior and exterior applications.

Phosphorescent powder coating for phosphorescent coating

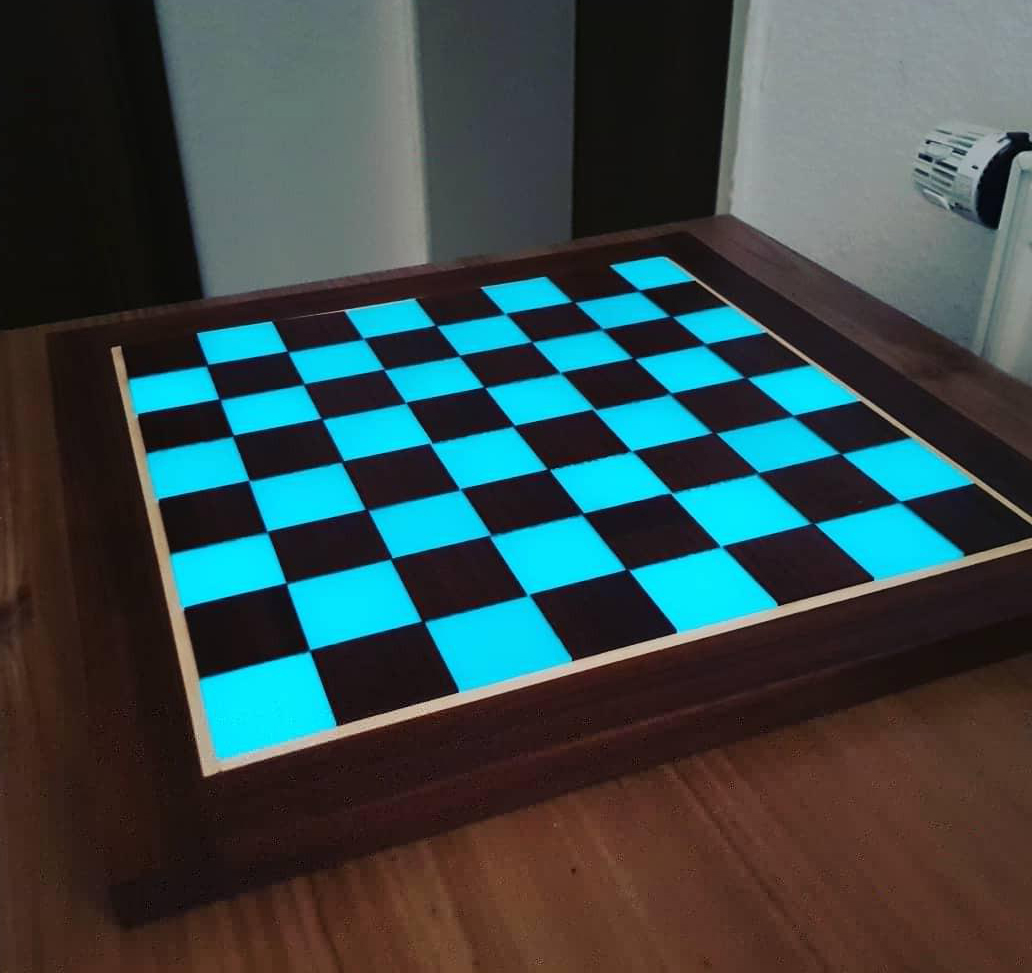

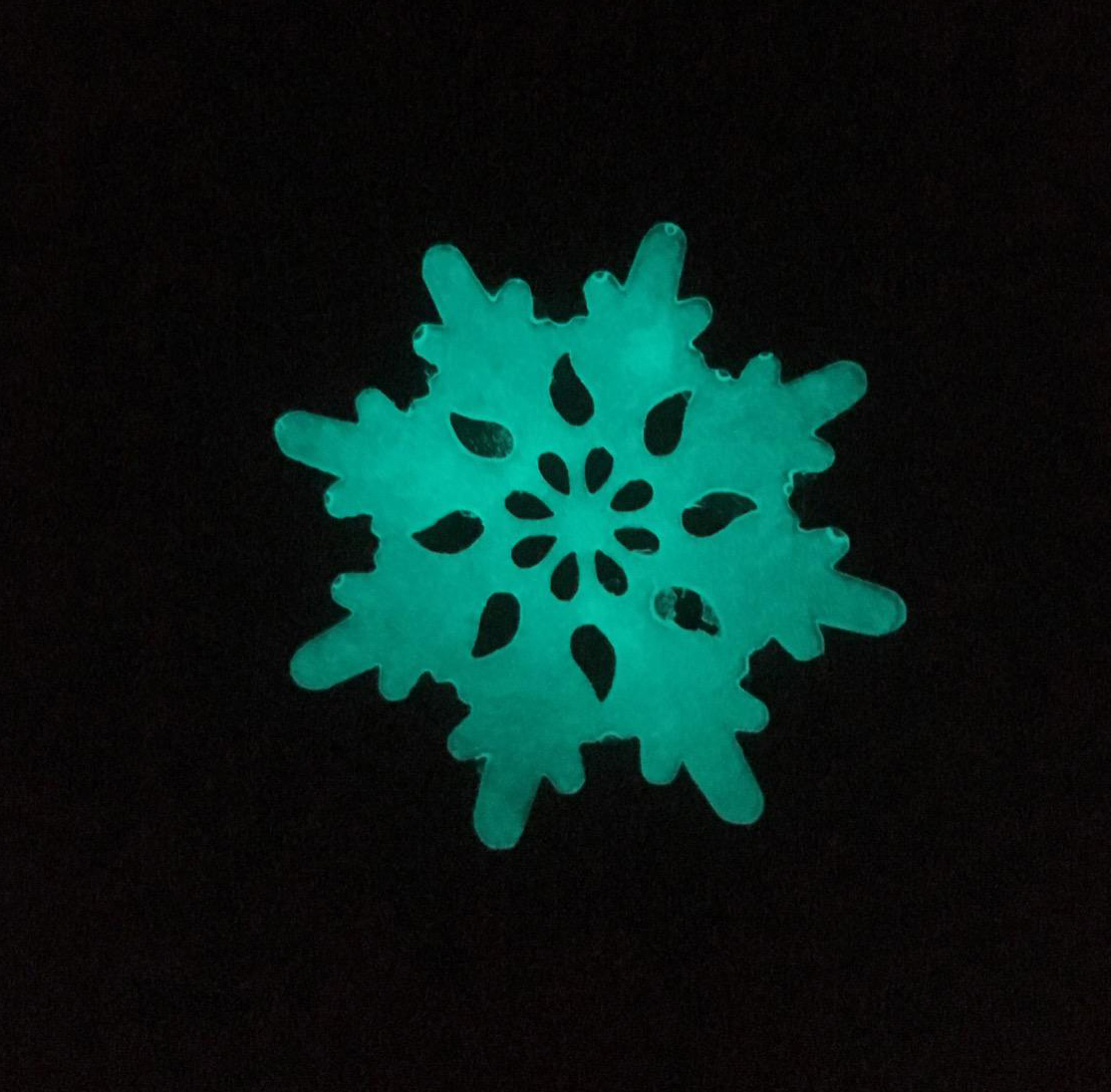

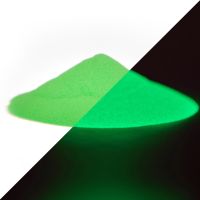

lumentics powder coating is a silk-matt, phosphorescent clear powder coating based on polyester. Suitable for interior and exterior coatings that glow in the dark. After exposure to UV light or black light, an afterglow effect becomes visible in the dark.

Our lumentics powder coating works like a light storage device: Daylight, artificial light or UV light charges the luminescent pigments contained in the coating and, in the dark, they release the stored energy as visible light over a period of several hours. The phosphor pigments also re-emit the light in water or indoors in complete darkness, among other things. This charging and afterglow process can be repeated indefinitely. The brightness and visibility duration are essentially dependent on the surface, the layer thickness and the activation intensity and duration.

Usage

Processing is the same as for other powder paints. The powder coating can be applied directly to a suitably prepared surface. For an ideal afterglow effect, it is always recommended to apply the paint to a white substrate. The phosphorescent effect is weather-resistant and color-stable.

Product information

- Special under black light phosphorescent clear powder coating

- Substrates: for metallic substrates; glass, ceramics and clay

- Gloss level: Silk matte

- Delivery form: powdery

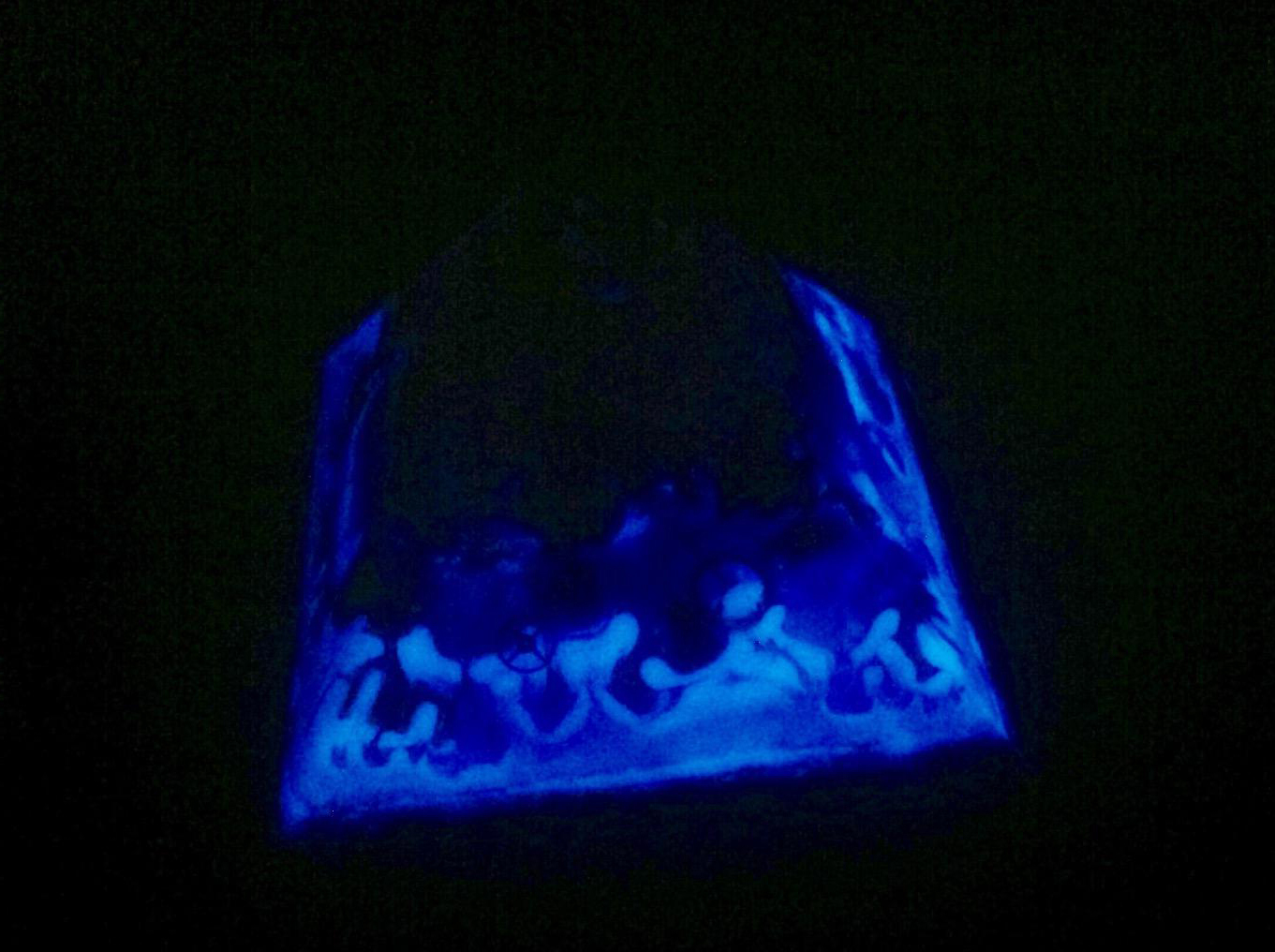

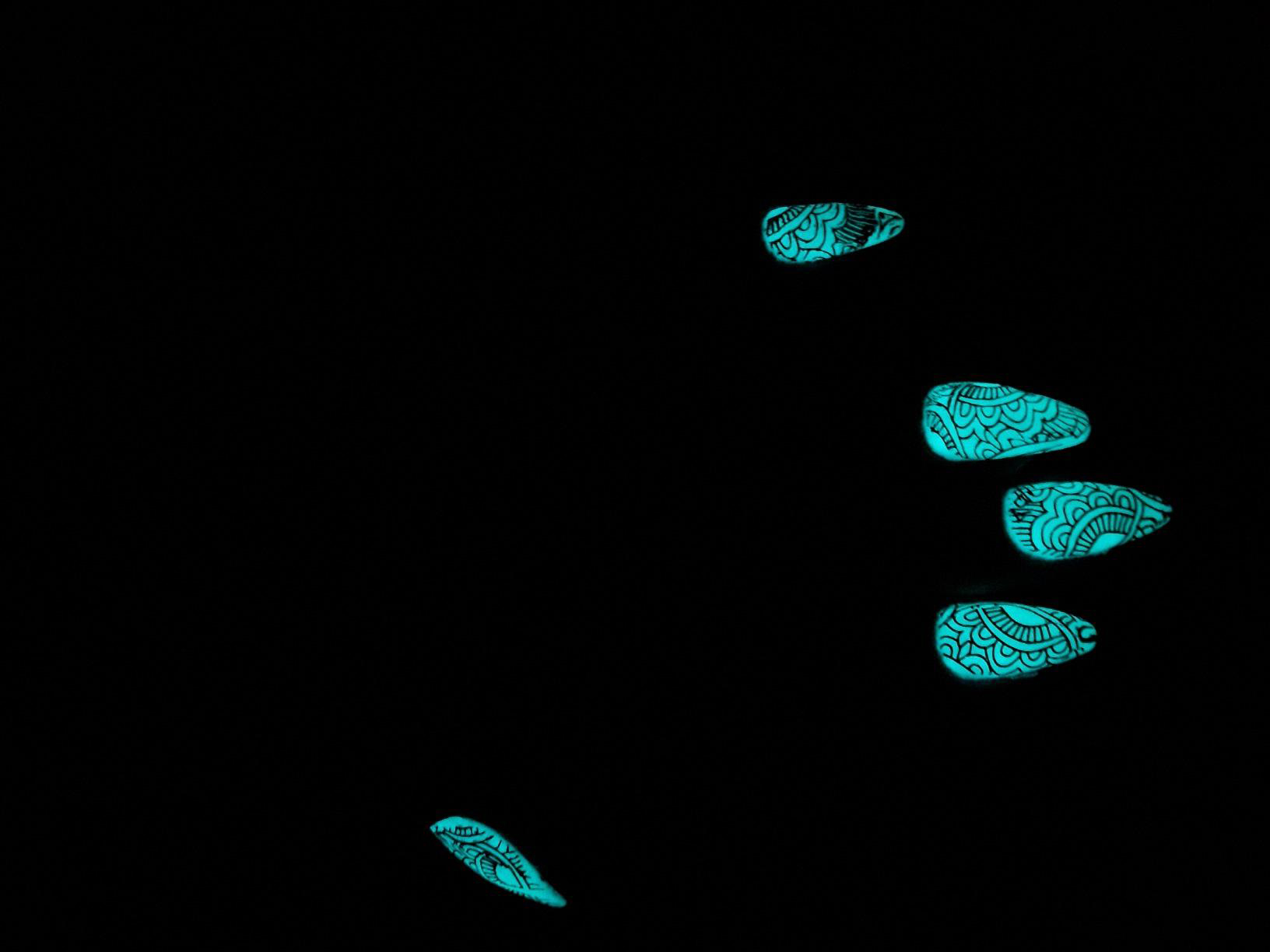

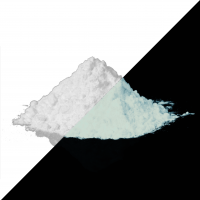

- Color: Semi-transparent/greenish-white by day/light ; Blue (slightly greenish) phosphorescent in darkness

- Excitation sources: Daylight and UV light (recommended); artificial light (e.g. lamps, flashlights, etc.).

- Application: Hand coating (Tribo, Corona)

- Effect: toxic class free; without any radioactivity

- Properties: hard, lacquered, smooth, satin, color stable, dimensionally stable, scratch resistant, heat resistant, splash water resistant, weather resistant, anti-corrosive

Application examples

- Marking escape routes

- Making obstacles and emergency exits recognizable

- Afterglow effect of safety-relevant objects such as door handles, light switches, handrails, stair edges or door frames

- Vehicle construction: controls and vehicle interiors

- Recreation, camping, sport fishing / fishing lures

- Artistic use in object and exhibition design

- Effective use in disco (black light parties), theater (dark shows) and sports (night mini golf)

Application classes/areas

- Coating & Painting

- Product & Industrial Design

- Safety & Security

- Advertising & Display

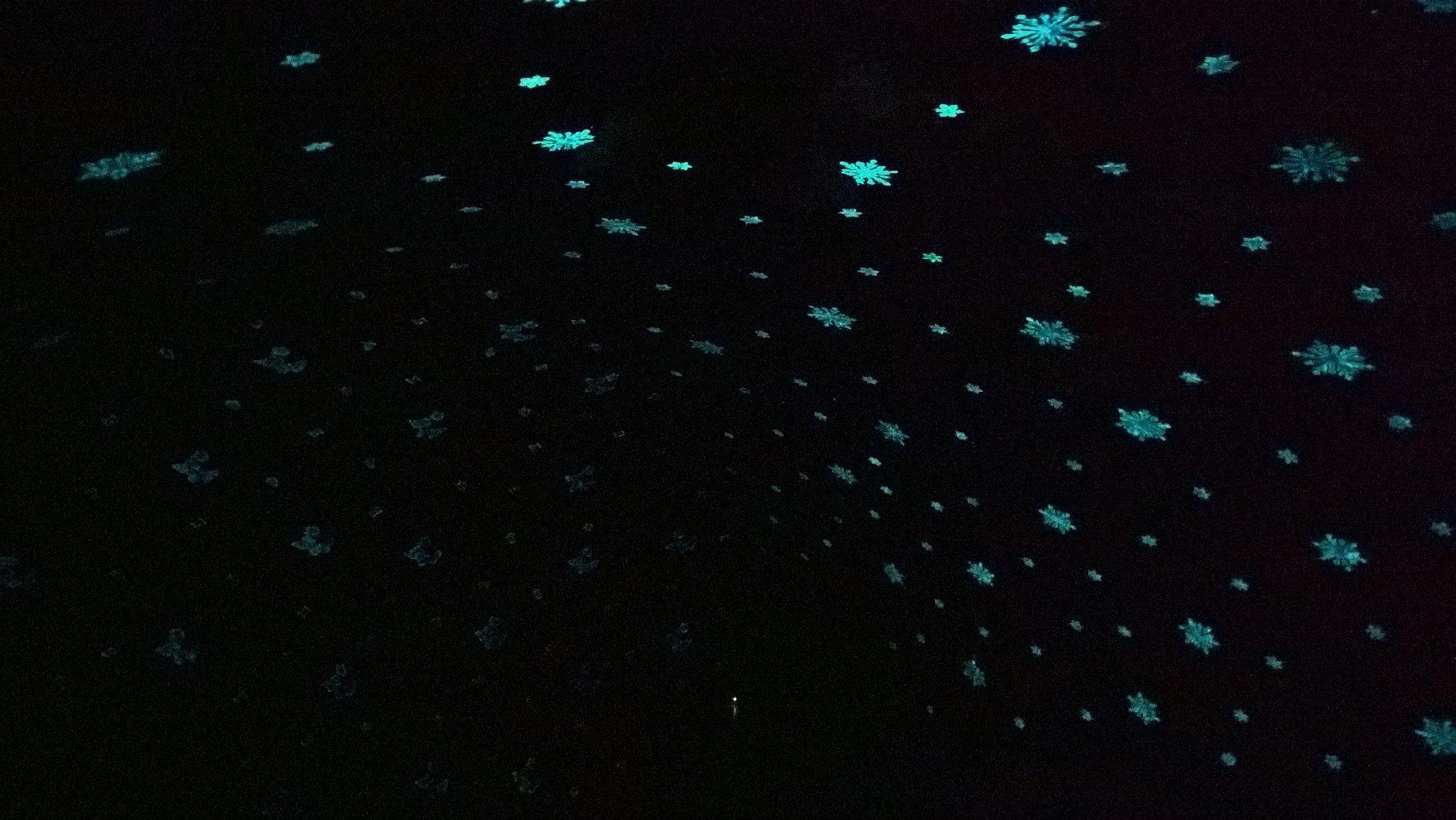

Practical examples and customer projects

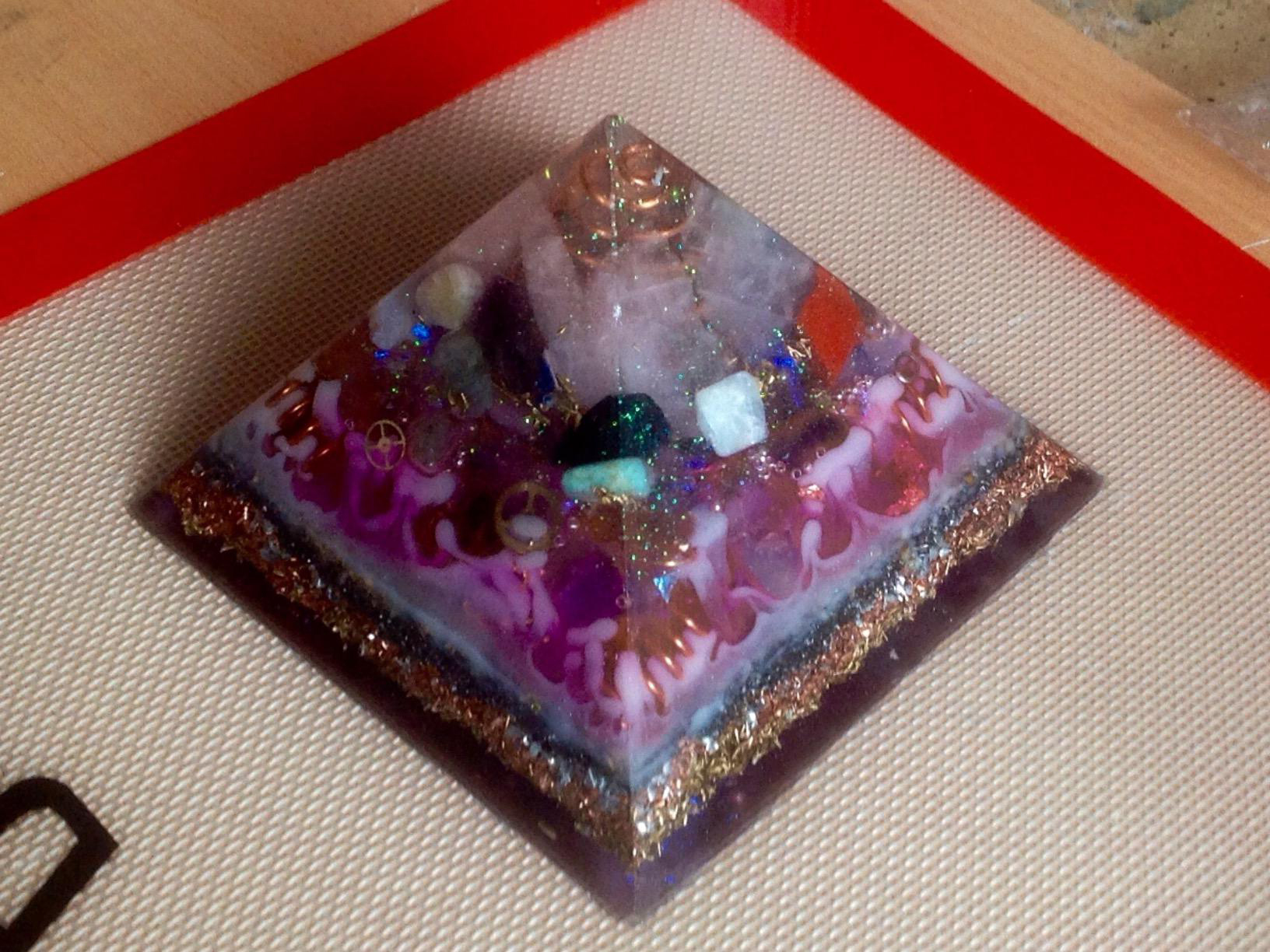

| Use case: | Painting, For epoxy/resin, For clear carrier fluids, For sprinkling and filling, Mould making, Mould casting, Works of art, Silicone objects, Body impression, Candle making, Jewellery making, Puppet making, Special effects, Special Make-Up, Prosthetics, Pouring, Nail varnish |

| Content: | 40 g |

| Effect: | Glows in the dark |

| Color in the dark: | Green |

| Color by light: | Nature/Whitish |

| Applicable with: | Brush (for liquid carrier material), Ink roller (for liquid substrate), Spray gun, Spray system, Airbrush systems |

| Pigment material: | Europium / dysprosium doped strontium aluminate |

| Water-soluble: | No |

| Working temperature (max): | 1.000° Celsius |

| Possible carriers: | Resin, Epoxy resin, Varnish, Adhesive, Glue, Wax, Kleister, Paint, Resin, Silicone, Sanitary silicone, Reactive resins, Acrylic binder, PU binder, Vinyl binder, Thermoplastics, Glass, Ammonia-free latex, Protective coating for wallpaper, Elephant skin, Wallpaper protector, Paint protection, Dispersion paint, Lithium water glass, Chalk paint, Skin adhesive, Latex, Latex milk, Rubber, Silicone rubber, Silicone gel, Condensation silicone, Varnish silicone, Addition silicone, Acrylic resin, Modelling clay, Plasticine, Moulding compound, Plaster, Alginate, Synthetic resin dispersion, Topcoat |

| Suitable for: | DIY, Hobby, Craft, Arts, Jewellery, Industry |

As a first step, perform a skin compatibility test on a 1 cm x 1 cm small spot on the arm, as everyone reacts differently to foreign substances. If no allergic reaction occurs, you can decorate your body without hesitation. To do this, mix the glow powders with special skin glue or adhesive fat cream.

An exception in the composition is the color pigment orange, because this is calcium sulfide, which is irritating according to the Ordinance on Hazardous Substances.

The phosphorescent professional color pigments store natural light and emit it again in darkness in a clearly visible way. Daylight, especially direct sunlight, is perfectly sufficient to stimulate the long-lasting luminosity of the colors. Electrically generated UV light (black light) can of course also be used for activation.

Depending on the product, charging via artificial light (light bulbs for room lighting and LED) is additionally possible (especially for blue-green and green).

Phosphorescent pigments are mixed with a carrier substance before application, which in the best case is clear and translucent. Then they can be applied directly.

Suitable is: casting resin, epoxy resin, tree resin, liquid plastics, wallpaper paste, transparent glue, hot glue, silicone, acrylic varnish, nail polish. Fixing spray, grease cream. For indoor areas, choose a solvent-free carrier. In the garden and, for example, for bicycles and cars, we recommend weather-resistant carrier liquid and sealing with an additional protective coating.

It is important that the pigments are not covered by darker / opaque particles, as in this case the luminosity is reduced. Test milky liquids to see if they become transparent during curing. In this case, you can use the pigments with them without any problems.

Mixing with other colors is generally possible with our professional products. However, the pigments should not be coated or covered by other colors, this would darken their luminosity. Observe the following instructions to maintain the luminosity in the best possible way: the lighter/ more translucent the other color, the more prominent the self-luminous color pigments will be. You can thin dark acrylic paints slightly and then incorporate the glow pigments with acyrl binder. You will get the best result if the noctilucent powders mixed with clear varnish are applied thinly to the painted picture. The pigments are whitish in daylight and appear like a slightly dusty layer on the painting when you look closely. However, the underlying color still stands out clearly.

lumentics tips

Due to the pigments' own weight, they may sink into water-based paints. You can thicken the carrier liquid with clear varnish before sprinkling.

For painting on paper and wallpaper, prime with white acrylic paint so that the pigments remain on the surface of the material.

For painting textiles, mixing with normal fabric paints is not sufficient. We advise to use transparent screen printing inks.

The luminous pigments are water-resistant due to a protective coating, they can be used, for example, to illuminate decorative fountains, aquariums or swimming pools. Due to the weight, they sink down in the water and do not float in the liquid, as known from a snow globe. They shine a little weaker from the bottom, because the pigments there can absorb less light.

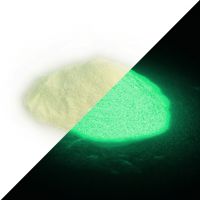

The offered Lumentics pigments are very high quality, the shades green and blue have an afterglow time of 8-12 hours. The pigment purple afterglows for 3 h and orange for about 1 h. The strongest luminosity is reached in the first half hour, then it gradually decreases. All pigments are guaranteed to be usable over and over again for up to 15 years and retain their properties.

Glow powders in the colors green and blue-green show the strongest afterglow effect. The blue pigments are less pronounced. The orange and purple versions radiate at a wavelength that is more difficult for the human eye to detect. Therefore, the luminosity appears lower than, for example, with the strongly luminous perceived colors green and blue-green. On dark backgrounds or as face paint, the purple-glow pigment stands out with difficulty. Mix in some blue-green powder if necessary.

The purple color pigment is very difficult to excite by light with a low UV content (e.g. an incandescent bulb).

The luminous pigments are supplied in a resealable bag and are white-yellowish in daylight. After charging, they glow in the dark in the desired color.

The premium glow powders are removable according to the description of the carrier substance. From textiles (without special fixation) and skin, the pigments can be removed well with soapy water.

The powders can be used over and over again for at least 15 years without losing their luminous properties.

The particle sizes of our premium annealing powders are 65-85 µm. This makes them ideal for incorporation into liquid binders. If you do not mix in our pigments but use them directly in the form of granules or as decorative pebbles, we recommend that you purchase our annealing granules.

The premium afterglow powders are ideal for use in hobbies, DIY, gardening, handicrafts, for beautifying walls and pictures - without having to rely on black light. Also in the safety area, e.g. for luminous signs, escape routes, bicycle helmets, etc., you can achieve the desired lasting luminous effect with the pigments.

The mixing ratio is ideally matched to the viscosity of the carrier liquid. A mixing ratio of one part glow powder to two parts carrier liquid (1:2) is appropriate in most cases. For dark mixed colors, you can sprinkle in slightly more luminescent pigments. The denser the pigment ratio, the stronger the luminosity. If the pigment ratio is too high, the mixture may form lumps. It is best to mix slowly while stirring constantly.

For incorporation into wall paint, the mixture of 1:1 - 1:3 is well suited, depending on the viscosity and brightness of the paint.

The mixed powders can be applied well with a narrow brush for fine drawings. Instead of one thick layer, it is better to apply several thin coats so that nothing runs. On useful surfaces (e.g. musical instruments, stair treads), seal the pigment layer with an impact-resistant transparent topcoat.

Glow in the dark paint green 250 ml - Glow in...

Glow in the dark paint green 250 ml - Glow in...  Glow in the dark paint green 250 ml - Glow in...

Glow in the dark paint green 250 ml - Glow in...  Glow in the dark paint green 250 ml - Glow in...

Glow in the dark paint green 250 ml - Glow in...