lumentics Premium DLP/SLA 3D Printing Resin - Innovation Made in Germany

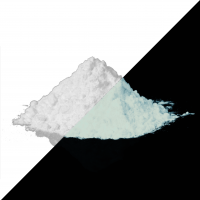

Our lumentics 3D resin is a glow-in-the-dark printing resin with excellent curing and strong afterglow effect. Our unique printing resin guarantees the best possible printing result: Clean, accurate and of course outstanding afterglow! All designed and manufactured for you in Germany.

Our DLP / SLA printing resin was specially developed for a strong afterglow effect combined with very good processing properties. And the whole thing as odourless as possible! Fast curing and ideal flowability are obligatory.

In addition to the great luminescent effect, we have succeeded in equipping the resin with a high level of stability. Lowest possible shrinkage and the possibility for high-resolution results round off the properties of our professional printer resin.

- INNOVATIVE: Glow-in-the-dark UV 3D printer resin from Germany. 500 g liquid afterglow mould resin for all common resin printers. Your objects will "glow" in the dark from now on!

- QUALITY: Developed and manufactured in Germany. 3D photopolymer resin for highest demands and professional printing results. Highest possible glow effect and low odour in processing.

- APPLICATION: "Glow in the Dark" liquid resin for hobby, industry, teaching and education. Can be used for DLP, SLA, LCD and LCS. For 3D printers, resin printers, 3D resin copiers and desktop 3D resin printers.

- WORKING RESULT: Our lumentics printing resin is the foundation for precise results, combined with high hardness and low shrinkage. 405 nm UV curing resin for prototyping and production.

- SAFE: Use and handle like conventional printer resin. Packaged in light-protected, leak-proof bottle. Safety data sheet is linked and also available on request.

Brief information

- The 3DResin prints like other types. No special settings necessary.

- The resin can be mixed with other printing resins (the luminous intensity then decreases in proportion).

- Mode of operation: The liquid 3D printer resin is cured with pinpoint accuracy during the printing process by means of a UV laser beam in a resin tank/basin, thus enabling an extremely detailed and smooth print image.

- Suitable for all common DLP printers with a UV source in the range of approx. 405 nm

- Suitable for the following printer types: Resin 3D printers, Resin printers, Resin 3D copiers, Resin desktop 3D printers.

- Suitable for the following printing technologies: Digital Light Processing (DLP), Stereolithography (SLA), Low Force Stereolithography (LFS), Liquid Crystal Display (LCD), Liquid Crystal Shutter (LCS).

- Additional terms: light-curing resin, photopolymer resin, rapid resin, UV resin, synthetic resin

- Packaging: Light-protected, leak-proof bottle

- Field of application: hobby, industry, school, educational institutions

Our (and therefore your) advantages: Product competence and specialist knowledge combine to create the highest innovation Made in Germany.

Hints for optimal use

The afterglow pigments in the printing resin may sink slightly during a longer printing process and the finished object may therefore glow somewhat unevenly.

Therefore, we recommend that you please observe the following points in order to achieve the best possible printing result:

- The print objects should be max. 10 cm high

- Shake the bottle intensively and well for at least 2 minutes (!) before pouring out to ensure an even pigment distribution

- Optional tip: Due to the thicker consistency, it may be advisable to increase the "lightoff time" slightly (possibly 1-2 seconds).

- Return the resin to the bottle after use in order to be able to reuse the remaining liquid.

Tips for use with the "Elegoo Mars"

(1) Due to the manufacturing process, the Elegoo Mars has a certain release coating on the printing platform. The original Elegoo material primarily adheres through this. To improve the adhesion, we recommend sanding the platform with sandpaper (not too coarse). With a burn-in layer exposure of at least 60 seconds, experience has shown that our printing resin (and also other, non-manufacturer materials) can be successfully printed.

(2) And still very important: The resin must be shaken for a long time (approx. 2 min) in order to distribute the luminescent pigments evenly!

(3) Practical settings for the Elegoo Mars

| Country of manufacture: | Germany |

Glow in the dark paint green 250 ml - Glow in...

Glow in the dark paint green 250 ml - Glow in...  Glow in the dark paint green 250 ml - Glow in...

Glow in the dark paint green 250 ml - Glow in...